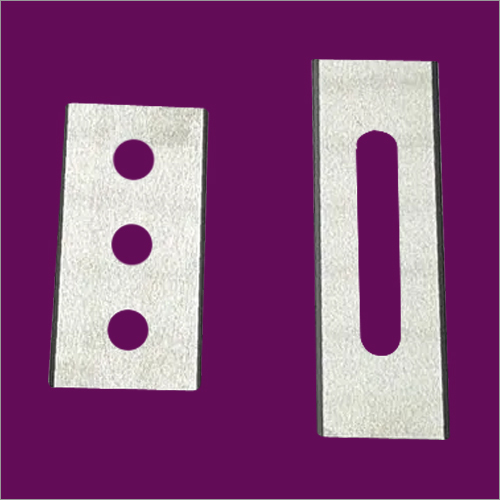

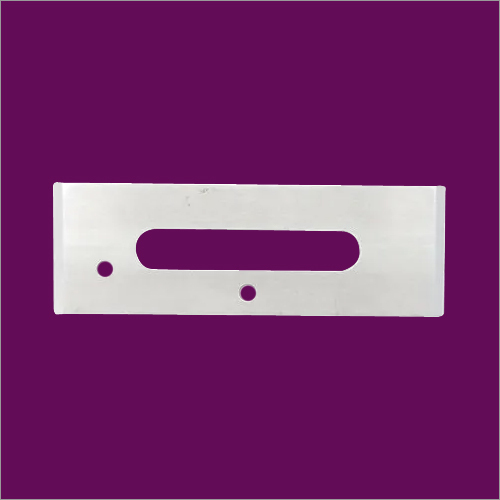

Tungsten Carbide Razor Blades

Price 100 INR/ Piece

MOQ : 100 Pieces

Tungsten Carbide Razor Blades Specification

- Precision

- High Precision

- Shape

- Rectangular

- Surface Treatment

- Polished

- Design

- Single Edge/Double Edge

- Type

- Industrial Razor Blade

- Blade Material

- Tungsten Carbide

- Application

- Slitting, Cutting, Trimming, Scraping

- Hardness

- 89-92 HRA

- Thickness

- 0.15 mm to 1.2 mm

- Sharpness

- Razor Sharp Edge

- Edge Trimming

- Customized as per requirement

- Finish

- Smooth Mirror Finish

- Tolerance

- ±0.01 mm

- Usage Life

- Extended/Long-Lasting

- Pack Type

- Plastic Storage Box or as specified

- Coating

- Optional TiN or TiAlN for increased durability

- Compatibility

- Fits all standard razor blade holders

- Corrosion Resistance

- Excellent

- Length

- Customized (Standard: 43 mm, 58 mm, 80 mm, or as required)

- Width

- Customized (Standard: 22 mm, 19 mm, or as required)

Tungsten Carbide Razor Blades Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 4-5 Days

About Tungsten Carbide Razor Blades

Experience an unprecedented price cut and enjoy top value on our grand range of Tungsten Carbide Razor Bladesdecorated with excellence in every aspect! Engineered for exceptional corrosion resistance and an extended usage life, these industrial razor blades boast razor-sharp edges and a smooth mirror finish. Customizable in length and width, their high precision ensures seamless slitting, cutting, and trimming. Optional TiN or TiAlN coating boosts durability, while advanced surface treatments deliver unmatched performance. Supplied in quality storage packs, these blades fit all standard holders, making them ideal for demanding applications worldwide.

Key Features and Application Areas

These Tungsten Carbide Razor Blades are distinguished by their high hardness of 89-92 HRA and razor-sharp single or double edges, with precision tolerances of 0.01 mm. Their polished, smooth finish and customizable design ensure suitability for slitting, cutting, trimming, and scraping in various industries. Common application areas include packaging, printing, paper, film, foil, and plastic processing, where long-lasting performance and minimized downtime are crucial.

Supply Ability, Certifications, and Sample Availability

We maintain a robust supply ability to meet bulk proposal amounts and support regular export market drop-offs worldwide. Samples are readily available for qualifying orders, allowing buyers to verify product quality upfront. Our blades come with relevant certifications, ensuring compliance with international standards for safety and precision. As a manufacturer, supplier, and exporter from India, we uphold rigorous quality controls throughout the production and logistical process.

Key Features and Application Areas

These Tungsten Carbide Razor Blades are distinguished by their high hardness of 89-92 HRA and razor-sharp single or double edges, with precision tolerances of 0.01 mm. Their polished, smooth finish and customizable design ensure suitability for slitting, cutting, trimming, and scraping in various industries. Common application areas include packaging, printing, paper, film, foil, and plastic processing, where long-lasting performance and minimized downtime are crucial.

Supply Ability, Certifications, and Sample Availability

We maintain a robust supply ability to meet bulk proposal amounts and support regular export market drop-offs worldwide. Samples are readily available for qualifying orders, allowing buyers to verify product quality upfront. Our blades come with relevant certifications, ensuring compliance with international standards for safety and precision. As a manufacturer, supplier, and exporter from India, we uphold rigorous quality controls throughout the production and logistical process.

FAQs of Tungsten Carbide Razor Blades:

Q: How are the Tungsten Carbide Razor Blades customized to fit specific requirements?

A: Each blades length, width, edge trimming, and surface finish can be precisely customized to match client specifications, ensuring compatibility with various applications.Q: What benefits does the optional TiN or TiAlN coating provide?

A: The optional TiN or TiAlN coating enhances blade durability, corrosion resistance, and cutting performance, extending the blades lifespan even under demanding conditions.Q: When is it best to request a sample before placing a bulk order?

A: Requesting a sample is recommended before confirming large proposal amounts or export market drop-offs, as it allows you to assess the blades quality and suitability for your application.Q: Where can these industrial razor blades be applied?

A: These blades are ideal for use in industries such as packaging, printing, plastic processing, film, foil, and paper manufacturing for slitting, trimming, and cutting tasks.Q: What is the process for ordering customized blades?

A: Contact us with your required dimensions, application details, and desired finish or coating. Our team will guide you through the customization and order process efficiently.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Razor Blades and Safety Knives Category

Industrial Razor Blades

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Precision : High precision

Edge Trimming : Perfectly honed

Type : Industrial Razor Blade

Sharpness : Ultrasharp edge

Ceramic Blades

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Precision : High

Edge Trimming : Fine

Type : Cutting Blade

Sharpness : Razor Sharp

We welcome both national and international inquiries.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS