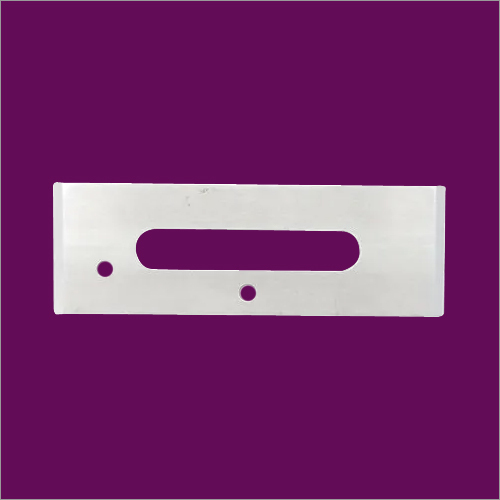

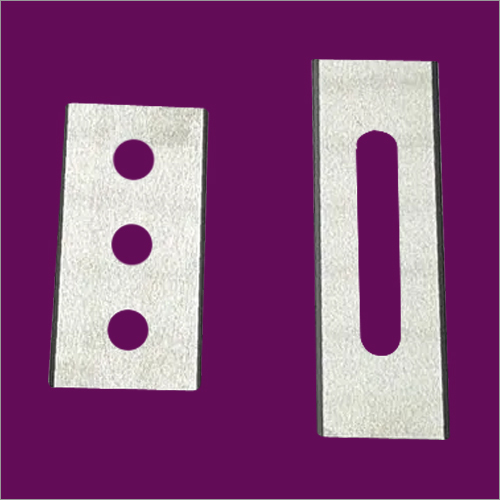

Ceramic Blades

Price 100 INR/ Piece

MOQ : 100 Pieces

Ceramic Blades Specification

- Shape

- Rectangular

- Precision

- High

- Surface Treatment

- Polished

- Design

- Double Edged

- Type

- Cutting Blade

- Blade Material

- Zirconia Ceramic

- Application

- Industrial Cutting, Paper, Film, Fiber, Plastic, Food Processing

- Hardness

- 8.5~9 Mohs

- Thickness

- 0.5 mm

- Sharpness

- Razor Sharp

- Edge Trimming

- Fine

- Finish

- Mirror Finish

- Width

- 18 mm

- Color

- White

- Conductivity

- Electrical Insulator

- Non-Magnetic

- Yes

- Corrosion Resistance

- Excellent

- Safety Feature

- Non-Sparking

- Wear Resistance

- High

- Temperature Resistance

- Up to 800°C

- Replacement Compatible

- Fits Various Utility Knife Handles

- Weight

- 5 g per blade

- Length

- 47 mm

Ceramic Blades Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 4-5 Days

About Ceramic Blades

Unlock advanced precision and explore a world of crowning efficiency with our Zirconia Ceramic Blades. Designed for inestimable durability, each blade measures 47 mm x 18 mm, boasting a razor-sharp double-edged profile and mirror finish. With excellent corrosion resistance, non-magnetic properties, high wear resistance, and temperature endurance up to 800C, these blades are crafted for industrial cutting, paper, film, fiber, plastics, and food processing. Advance purchase ensures you harness safety features like non-sparking and fine edge trimming. Compatible with various utility knife handles, these blades embody excellence from Indias leading exporter, manufacturer, supplier, and service provider.

Versatile Application Areas for Ceramic Blades

Ceramic blades elevate your cutting operations beyond basic tasks. Their robust design and high hardness enable seamless applications across industrial settings, paper trimming, film cutting, fiber slicing, plastic processing, and food handling. Widely utilized in manufacturing units, laboratories, packaging industries, and craft workshops, these blades ensure reliable, fine cuts every time. Their adaptability suits diverse usage scenarios, advancing performance and precision in both automated and manual cutting procedures.

Efficient Supply and Delivery Estimates for Ceramic Blades

Our supply ability consistently meets bulk and custom orders, supported by prompt delivery schedules and real-time arrival tracking. Benefit from flexible payment terms designed for smooth transactions. Samples are available, allowing assessment of sharpness and performance before commitment. Delivery turnaround and estimated arrival times depend on your location but we ensure products reach you swiftly. Partner with us for reliable supply solutions and a seamless purchasing experience, elevating your industrial cutting endeavors.

Versatile Application Areas for Ceramic Blades

Ceramic blades elevate your cutting operations beyond basic tasks. Their robust design and high hardness enable seamless applications across industrial settings, paper trimming, film cutting, fiber slicing, plastic processing, and food handling. Widely utilized in manufacturing units, laboratories, packaging industries, and craft workshops, these blades ensure reliable, fine cuts every time. Their adaptability suits diverse usage scenarios, advancing performance and precision in both automated and manual cutting procedures.

Efficient Supply and Delivery Estimates for Ceramic Blades

Our supply ability consistently meets bulk and custom orders, supported by prompt delivery schedules and real-time arrival tracking. Benefit from flexible payment terms designed for smooth transactions. Samples are available, allowing assessment of sharpness and performance before commitment. Delivery turnaround and estimated arrival times depend on your location but we ensure products reach you swiftly. Partner with us for reliable supply solutions and a seamless purchasing experience, elevating your industrial cutting endeavors.

FAQs of Ceramic Blades:

Q: How does the non-magnetic property of ceramic blades benefit users?

A: The non-magnetic property eliminates interference in environments sensitive to magnetism, making these blades ideal for laboratories, electronics, and cleanroom applications where magnetic contamination is undesirable.Q: What is the process for purchasing samples of these ceramic blades?

A: Simply contact our sales team or fill out a request form on our website to arrange sample delivery. Samples are available to help you evaluate sharpness, performance, and compatibility before placing a bulk or advance purchase order.Q: Where can these ceramic blades be used outside of industrial cutting?

A: Besides industrial cutting, our ceramic blades are suitable for food processing, paper and film trimming, fiber slicing, laboratory use, and crafts. Their excellent properties make them versatile across multiple sectors.Q: When should the ceramic blade be replaced for optimal performance?

A: Replace the blade when you notice diminished sharpness or reduced cutting efficiency. Its wear resistance means fewer replacements are needed, but timely replacement ensures consistent, precise results.Q: What steps ensure safe usage of ceramic blades in the workplace?

A: Use compatible utility knife handles, keep fingers away from the cutting edge, and utilize the non-sparking feature for added safety. Always adhere to workshop safety guidelines during operation.Q: How does the ceramic blades high temperature resistance enhance its usage?

A: The temperature resistance up to 800C allows these blades to perform in extreme heat conditions without degrading, making them suitable for high-temperature manufacturing and food processing applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Razor Blades and Safety Knives Category

Industrial Razor Blades

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Edge Trimming : Perfectly honed

Precision : High precision

Type : Industrial Razor Blade

Design : Other, Doubleedged

Tungsten Carbide Razor Blades

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Edge Trimming : Customized as per requirement

Precision : High Precision

Type : Industrial Razor Blade

Design : Other, Single Edge/Double Edge

We welcome both national and international inquiries.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS