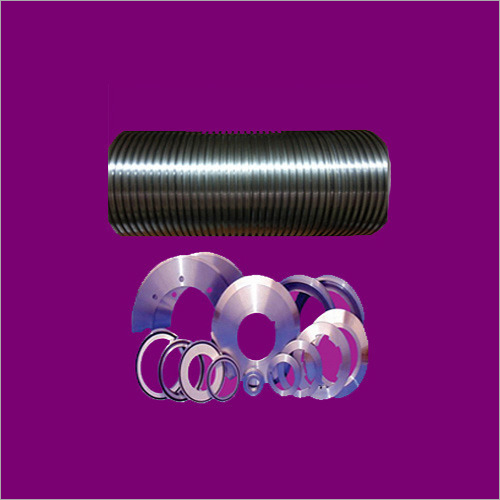

Top and Bottom Slitting Knives

Price 100 INR/ Piece

MOQ : 100 Pieces

Top and Bottom Slitting Knives Specification

- Surface Treatment

- Polished

- Shape

- Round

- Precision

- High Accuracy

- Design

- Industrial Standard

- Type

- Top and Bottom Slitting Knives

- Blade Material

- High Speed Steel (HSS), Alloy Tool Steel

- Application

- Slitting, Rewinding, and Shearing Operations in Paper, Film, Foil, and Metal Industries

- Hardness

- 58-62 HRC

- Thickness

- 1 mm to 20 mm

- Sharpness

- Razor Edge

- Edge Trimming

- Smooth and Burr-free

- Finish

- Fine Mirror Finish

- Compatibility

- All Standard Slitting Machines

- Wear Resistance

- Excellent

- Inner Diameter Tolerance

- +0.01 mm/-0.02 mm

- Re-grindable

- Yes

- Heat Treatment

- Vacuum Hardened

- Production Method

- CNC Machined

- Corrosion Resistance

- Yes

- Cutting Angle

- Customizable as per application

- Outer Diameter Range

- 80 mm to 400 mm

Top and Bottom Slitting Knives Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 4-5 Days

About Top and Bottom Slitting Knives

Ace your industrial cutting operations with our top and bottom slitting knives, now available at a reduced price under our special promotion. Remarked for transcendent precision, each knife boasts an outer diameter range from 80 mm to 400 mm and vacuum-hardened corrosion resistance for prolonged service. With custom cutting angles, re-grindable razor edges, and smooth burr-free trimming, these CNC-machined blades ensure high accuracy and exceptional wear resistance. Take advantage of this offercompatible with all standard slitting machines. Produced in India using HSS and alloy tool steel, each blade features fine mirror finishing, making it the intelligent choice for rewinding and shearing in paper, film, foil, and metal applications.

Precision Features & Surface Versatility

Our top and bottom slitting knives are crafted to excel in multiple applications, including slitting, rewinding, and shearing in paper, film, foil, and metal sectors. Extra features, such as high hardness (58-62 HRC), heat-treated vacuum hardening, and mirror polish finishing, ensure a smooth and burr-free edge. The industrial standard design, round shape, and CNC machining provide transcendent accuracy and compatibility with all standard slitting machinery. Each blade is corrosion-resistant and wear-resistant for long-lasting performance.

Sample, Payment Options & Packaging Details

We offer sample kits at the lowest price and guarantee safe goods transport for prompt handover. Flexible payment terms cater to customer convenience, providing various options to suit your procurement process. Our products are precisely packaged, ensuring secure delivery and pristine condition upon arrival. Experience hassle-free ordering with comprehensive support from production to delivery for our slitting knives, and benefit from a transparent, customer-focused approach for every purchase.

Precision Features & Surface Versatility

Our top and bottom slitting knives are crafted to excel in multiple applications, including slitting, rewinding, and shearing in paper, film, foil, and metal sectors. Extra features, such as high hardness (58-62 HRC), heat-treated vacuum hardening, and mirror polish finishing, ensure a smooth and burr-free edge. The industrial standard design, round shape, and CNC machining provide transcendent accuracy and compatibility with all standard slitting machinery. Each blade is corrosion-resistant and wear-resistant for long-lasting performance.

Sample, Payment Options & Packaging Details

We offer sample kits at the lowest price and guarantee safe goods transport for prompt handover. Flexible payment terms cater to customer convenience, providing various options to suit your procurement process. Our products are precisely packaged, ensuring secure delivery and pristine condition upon arrival. Experience hassle-free ordering with comprehensive support from production to delivery for our slitting knives, and benefit from a transparent, customer-focused approach for every purchase.

FAQs of Top and Bottom Slitting Knives:

Q: How can I request a sample of top and bottom slitting knives?

A: You can request a sample by contacting us directly through our website or customer support team. We offer sample kits at the lowest price to help you evaluate product compatibility and performance before bulk ordering.Q: What payment terms are available for slitting knife orders?

A: We provide flexible payment terms to suit your purchasing preferences, including advance payment options, easy installments, and secure online transactions. All payment terms are transparent and discussed upfront to ensure customer satisfaction.Q: Where are the top and bottom slitting knives shipped from?

A: All products are shipped from our manufacturing facility in India. We use reliable goods transport methods to ensure swift and safe handover, with tracking available for each shipment.Q: What is the process for customizing the cutting angle of the knives?

A: Custom cutting angles are available as per your specific application requirements. Simply share your desired specifications with our technical team during the inquiry stage, and we will manufacture the knives accordingly using CNC machining for precision.Q: When should the slitting knives be re-ground for optimal performance?

A: Re-grinding is recommended when the edge loses its razor sharpness or smoothness. Our knives are designed to be re-grindablewith proper service, you can maintain high performance and extend blade life significantly.Q: What are the primary benefits of using your slitting knives in industrial operations?

A: Our slitting knives deliver exceptional accuracy, mirror finish, outstanding wear and corrosion resistance, smooth edge trimming, and compatibility with all standard slitting machines, improving productivity and reducing operational costs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Knives For Paper Industries Category

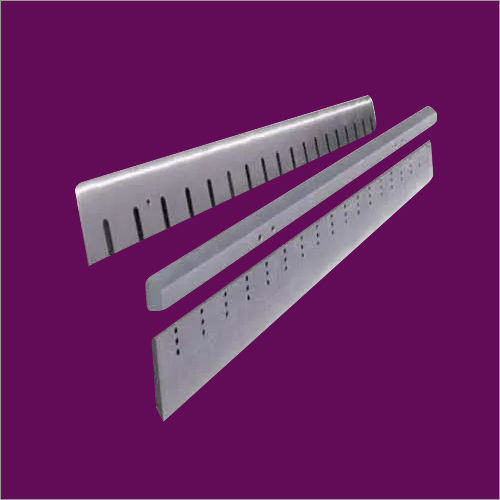

Sheet Cutting Knives

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Type : Sheet Cutting Knife

Sharpness : IndustrialGrade Sharp

Surface Treatment : Other , Polished

Blade Material : Other, High Speed Steel / Alloy Steel

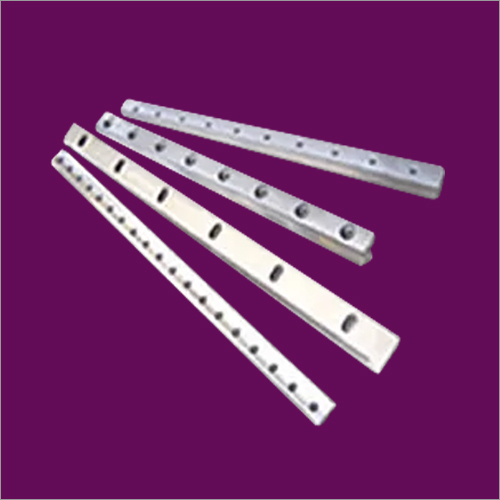

Multiple Edge Bottom Knives

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Type : Bottom Knife

Sharpness : Razor Sharp

Surface Treatment : Other , Polished and Coated

Blade Material : Other, High Speed Steel, Alloy Steel

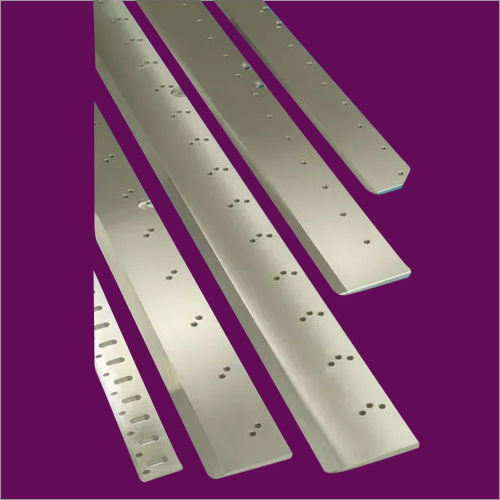

Sheeter Knives

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Type : Sheeter Knife

Sharpness : Razor Sharp

Surface Treatment : Other , Polished

Blade Material : Other, Alloy Tool Steel

We welcome both national and international inquiries.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS