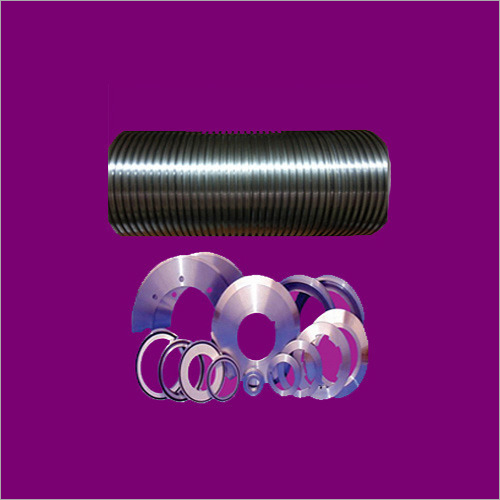

Multiple Edge Bottom Knives

Price 100 INR/ Piece

MOQ : 100 Pieces

Multiple Edge Bottom Knives Specification

- Precision

- High Precision

- Shape

- Round

- Design

- Multiple Edge, Customized

- Surface Treatment

- Polished and Coated

- Type

- Bottom Knife

- Blade Material

- High Speed Steel, Alloy Steel

- Application

- Slitting, Cutting, Trimming for Industrial Uses

- Hardness

- Up to 65 HRC

- Thickness

- 1 mm to 10 mm

- Sharpness

- Razor Sharp

- Edge Trimming

- Multiple Edge for Efficient Trimming

- Finish

- Mirror Finish

- Heat Treatment

- Vacuum heat treated

- Service Life

- Extended life for continuous operations

- Tolerance

- ±0.01 mm

- Maintenance

- Easy to regrind and maintain

- Wear Resistance

- Excellent wear and tear resistance

- Diameter Range

- 50 mm to 350 mm

- Packaging

- Individual anti-rust packaging

- Cutting Angle

- Multi-angle micro and macro edge

- Compatibility

- Compatible with various slitter machines

- Customization

- Available for thickness, diameter, and hardness

Multiple Edge Bottom Knives Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 4-5 Days

About Multiple Edge Bottom Knives

Hot deal alert for those seeking must-have precision: our Multiple Edge Bottom Knives are the ineffable solution for valiant industrial cutting. Designed with a diameter range from 50 mm to 350 mm and a razor-sharp, multi-angle edge, these top-drawer knives boast high precision and extended service life. Their excellent wear resistance and vacuum heat treatment ensure consistent performance, while customizable options meet unique application demands. Packaged in anti-rust wraps for maximum care and compatibility with various slitter machines, these are prized by manufacturers across India. Pick yours for exceptional, long-lasting performance!

Versatile Applications Across Industrial Sectors

Multiple Edge Bottom Knives are ideal for slitting, trimming, and cutting across various industries, including paper, film, foil, and metal converting. With their superb wear resistance and high precision, these knives excel in challenging factory environments, processing plants, and large-scale manufacturing sites. Specifically designed for slitter machines, their multi-edge structure delivers consistent, top-quality results, making them indispensable for maximizing process efficiency in sectors like packaging, textiles, and industrial fabrication.

Precision Packaging and Rapid Domestic Delivery

Each Multiple Edge Bottom Knife is individually packaged with anti-rust protection to ensure pristine arrival. Dispatching is efficient, with prompt rates to all major domestic markets in India such as Delhi, Mumbai, and Chennai. Sample availability allows customers to evaluate product quality before bulk orders. Our seamless logistics keep rates competitive and ensure your knives reach their destination rapidly, maintaining their integrity and readiness for immediate use after arrival.

Versatile Applications Across Industrial Sectors

Multiple Edge Bottom Knives are ideal for slitting, trimming, and cutting across various industries, including paper, film, foil, and metal converting. With their superb wear resistance and high precision, these knives excel in challenging factory environments, processing plants, and large-scale manufacturing sites. Specifically designed for slitter machines, their multi-edge structure delivers consistent, top-quality results, making them indispensable for maximizing process efficiency in sectors like packaging, textiles, and industrial fabrication.

Precision Packaging and Rapid Domestic Delivery

Each Multiple Edge Bottom Knife is individually packaged with anti-rust protection to ensure pristine arrival. Dispatching is efficient, with prompt rates to all major domestic markets in India such as Delhi, Mumbai, and Chennai. Sample availability allows customers to evaluate product quality before bulk orders. Our seamless logistics keep rates competitive and ensure your knives reach their destination rapidly, maintaining their integrity and readiness for immediate use after arrival.

FAQs of Multiple Edge Bottom Knives:

Q: How does the multiple edge design enhance cutting performance?

A: The multiple edge structure provides efficient and consistent trimming, slitting, and cutting. This design ensures clean cuts and extends the service life of each knife, reducing maintenance frequency and downtime in industrial operations.Q: What applications are best suited for these bottom knives?

A: These knives are perfect for use in slitting, trimming, and cutting applications in industries such as packaging, textiles, paper, film, and metal processing. Their compatibility with various slitter machines makes them versatile across numerous industrial uses.Q: How is the precision and sharpness of the knives maintained over time?

A: Thanks to vacuum heat treatment, high-quality steel materials, and mirror-finished coating, the knives offer both high precision and razor sharpness. They are also designed for easy regrinding and routine maintenance, preserving cutting performance through sustained use.Q: What packaging measures ensure product safety during delivery?

A: Every knife is individually wrapped with anti-rust packaging, safeguarding it against corrosion and damage during transportation. This carefully considered packaging ensures the product arrives in optimal condition, ready for immediate deployment.Q: Can I request customized specifications for diameter, thickness, or hardness?

A: Yes, customization is available for diameter, thickness, hardness, and edge profile. You can specify your requirements during the ordering process to ensure the knives meet your operational needs precisely.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Knives For Paper Industries Category

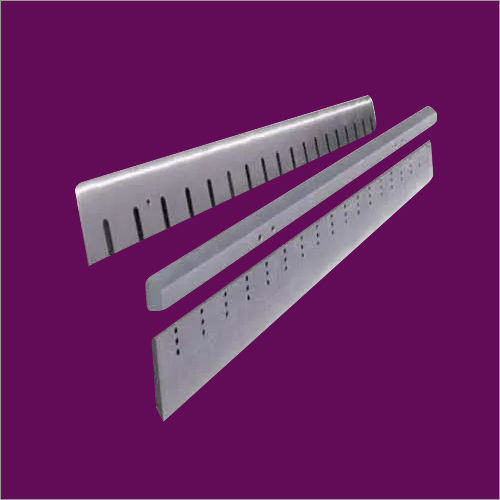

Sheet Cutting Knives

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Sharpness : IndustrialGrade Sharp

Type : Sheet Cutting Knife

Hardness : 5862 HRC

Thickness : 2mm to 10mm

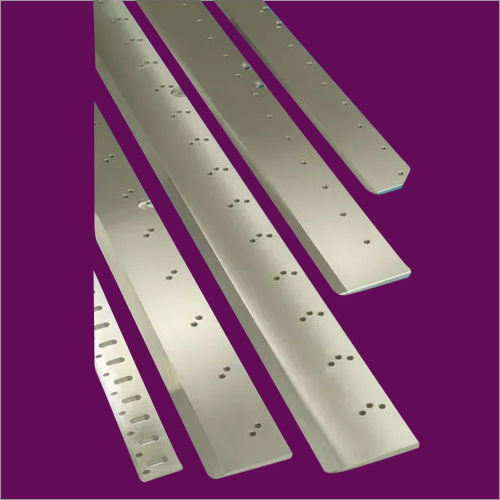

Top and Bottom Slitting Knives

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Sharpness : Razor Edge

Type : Top and Bottom Slitting Knives

Hardness : 5862 HRC

Thickness : 1 mm to 20 mm

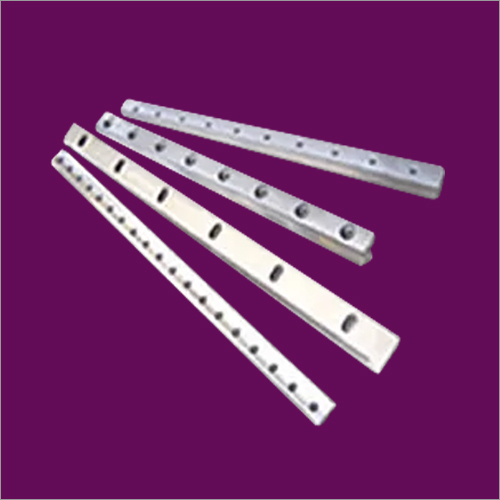

Sheeter Knives

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Sharpness : Razor Sharp

Type : Sheeter Knife

Hardness : 5658 HRC

Thickness : 6 mm

We welcome both national and international inquiries.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS