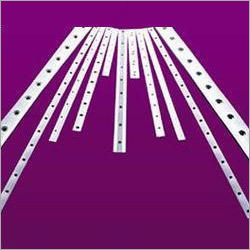

Slitting Cutter Blades

Price 100 INR/ Piece

Slitting Cutter Blades Specification

- Shape

- Round

- Precision

- High Precision

- Design

- Single and Multi Slit

- Surface Treatment

- Polished

- Type

- Industrial Slitting Cutter Blade

- Blade Material

- High Speed Steel (HSS) / Tungsten Carbide

- Application

- Paper, Film, Foil, Textile and Metal Slitting

- Hardness

- 58-62 HRC

- Thickness

- 0.5 mm to 6 mm

- Sharpness

- Razor Sharp Edge

- Edge Trimming

- Clean and Burr-free

- Finish

- Mirror Finish

- Diameter

- 50 mm to 300 mm

- Corrosion Resistance

- Yes

- Customization

- Available as per Client Specification

- Life Span

- Long Service Life

- Packing

- Individual Protective Cover or as Required

- Brand Compatibility

- Universal / OEM Specifications

- Usage

- Rotary and Automatic Cutting Machines

- Heat Treatment

- Vacuum Hardened

- Cutting Performance

- Consistent and Durable Cutting

- Color

- Metallic Silver

- Tolerance

- ±0.01 mm

Slitting Cutter Blades Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 4-5 Days

About Slitting Cutter Blades

Applications & Versatility of Slitting Cutter Blades

Slitting Cutter Blades are specially designed for both general and specific industrial use. Whether youre slicing through paper, film, foil, textiles, or metal, these blades deliver high precision and consistent performance. Their versatile round shape and availability in single or multi-slit designs make them perfect for rotary and automatic cutting machines. Key features include remarkable sharpness, clean edge trimming, corrosion resistance, and a robust mirror finish, meeting the needs of demanding industrial applications in diverse environments.

Packaging, Supply, and Delivery for Market Value

Every Slitting Cutter Blade is individually protected or packed as per client requirements, ensuring market value and pristine arrival. With substantial supply ability, we guarantee timely fulfillment of bulk or custom orders. Our express shipping services ensure quick delivery, reducing downtime and meeting urgent demands. As a reliable exporter, manufacturer, and supplier from India, we prioritize secure, efficient logistics and provide up-to-date tracking for every shipment, ensuring your investment arrives on time and in perfect condition.

FAQs of Slitting Cutter Blades:

Q: How are the slitting cutter blades customized for unique client requirements?

A: Customization is available based on client specifications regarding size, thickness, edge type, and material. Clients can provide details, and our manufacturing team ensures precision tailoring, suitable for various applications and machinery.Q: What makes these blades suitable for universal or OEM machine compatibility?

A: Each blade is engineered with stringent tolerance controls (0.01 mm) and universal design, allowing seamless integration into most rotary and automatic machines, including those that follow OEM specifications.Q: Where are these slitting cutter blades commonly used?

A: They are widely used in industries processing paper, film, foil, textiles, and metals, ensuring reliable slitting and edge trimming in both general and specialized cutting applications.Q: What is the benefit of vacuum hardened and polished surface treatments?

A: Vacuum hardening enhances hardness (58-62 HRC) and extends blade life, while polished and mirror finishes reduce friction, improve cutting efficiency, and maintain cleanliness during operation.Q: How is the packaging designed to protect the blades during transit?

A: Each blade is delivered in an individual protective cover or customized packaging as needed, safeguarding it from physical damage, corrosion, and contamination until it arrives at your facility.Q: When can customers expect arrival after placing an order?

A: With express shipping and robust supply capabilities, orders are dispatched promptly and reach clients swiftly. Delivery times may vary by location, but most shipments are expedited for timely arrival.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Working Blades Category

Section Steel Shear Blades

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Surface Treatment : Other , Polished

Edge Trimming : Smooth Edge Trimming

Application : Steel Bar and Section Shearing

Precision : High Precision

Shearing Blades

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Surface Treatment : Other , Polished

Edge Trimming : Laser Edge Ground

Application : Steel Sheet Cutting, Industrial Shearing Machines

Precision : High Precision

Metal Slitting Blades

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Surface Treatment : Other , Polished

Edge Trimming : Accurate edge trimming capability

Application : Slitting and cutting of metal sheets, coils, and strips

Precision : High precision

Fly Shearing Blades

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Surface Treatment : Other , Polished

Edge Trimming : Microfinished edge for burrfree cuts

Application : Used for cutting steel and metal sheets in fly shearing machines

Precision : High Precision

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS