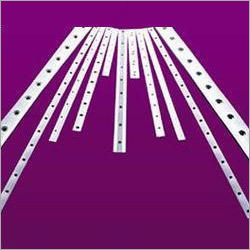

Fly Shearing Blades

Price 100 INR/ Piece

Fly Shearing Blades Specification

- Design

- Rectangular with beveled edges

- Precision

- High Precision

- Shape

- Straight

- Surface Treatment

- Polished

- Type

- Industrial Cutting Blade

- Blade Material

- High-grade High-Speed Steel (HSS)

- Application

- Used for cutting steel and metal sheets in fly shearing machines

- Hardness

- 58-62 HRC

- Thickness

- 12 mm

- Sharpness

- Razor-sharp edge for clean shearing

- Edge Trimming

- Micro-finished edge for burr-free cuts

- Finish

- Mirror Finished

- Compatibility

- Suitable for various fly shearing machine models

- Corrosion Resistance

- Yes, anti-corrosive coating

- Width

- 50 mm

- Temperature Resistance

- Up to 550°C

- Length

- 150 mm

- Weight

- 850 grams

- Maintenance

- Requires periodic sharpening

Fly Shearing Blades Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 4-5 Days

About Fly Shearing Blades

Superior Cutting Precision

Fly Shearing Blades are manufactured to deliver high-precision cuts, with razor-sharp edges and micro-finished trimming, ensuring steel and metal sheets are sheared cleanly and efficiently. Their straight, rectangular design with beveled edges supports consistent, burr-free results.

Durable High-Speed Steel Construction

Crafted from high-grade HSS, these blades offer outstanding durability, hardness of 58-62 HRC, and resilience against wear. The blades are engineered for heavy-duty industrial applications, making them ideal for continuous use in demanding environments.

Excellent Corrosion and Temperature Resistance

The blades feature advanced anti-corrosive coatings and polished surface treatments, enabling operation in harsh conditions. With resistance to temperatures up to 550C, they perform reliably without degradation, extending service life.

FAQs of Fly Shearing Blades:

Q: How should Fly Shearing Blades be maintained for optimal performance?

A: To ensure sharpness and high-quality cuts, Fly Shearing Blades should be periodically sharpened using professional-grade sharpening tools, following standard maintenance schedules based on usage frequency.Q: What materials are Fly Shearing Blades designed to cut?

A: These blades are specifically designed to cut steel and metal sheets in fly shearing machines, offering clean and precise shearing for industrial fabrication processes.Q: When is it recommended to replace or resharpen the blades?

A: Blades should be resharpened when a decline in cutting efficiency or increased burr formation is noticed. Replacement is advised if wear becomes excessive or sharpening can no longer restore edge quality.Q: Where can these blades be used?

A: Fly Shearing Blades are compatible with a wide range of fly shearing machine models, making them suitable for steel plants, metal fabrication units, and other industrial settings across India and globally.Q: What process ensures the blades remain corrosion-resistant?

A: An anti-corrosive coating is applied during manufacturing, alongside polished and mirror finishing treatments, providing robust protection against rust and environmental wear.Q: How does using these blades benefit industrial cutting operations?

A: Utilizing these blades ensures high-precision, burr-free cuts, increased operational efficiency, reduced downtime, and longer blade life, essential for productivity in steel and metal processing industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Working Blades Category

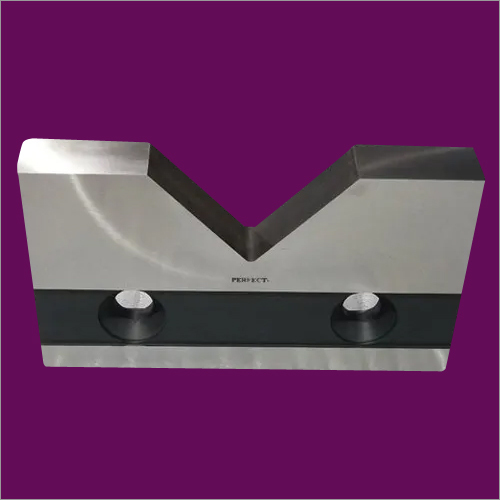

Section Steel Shear Blades

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Edge Trimming : Smooth Edge Trimming

Finish : Smooth

Application : Steel Bar and Section Shearing

Thickness : 25 mm

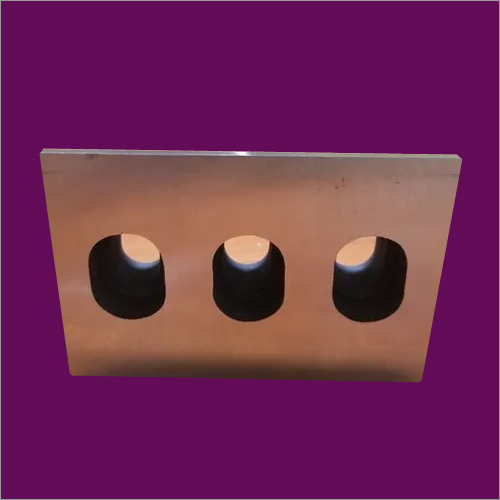

Shearing Blades

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Edge Trimming : Laser Edge Ground

Finish : Mirror Finish

Application : Steel Sheet Cutting, Industrial Shearing Machines

Thickness : 550 mm (customizable)

Slitting Cutter Blades

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Edge Trimming : Clean and Burrfree

Finish : Mirror Finish

Application : Paper, Film, Foil, Textile and Metal Slitting

Thickness : 0.5 mm to 6 mm

Metal Slitting Blades

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Edge Trimming : Accurate edge trimming capability

Finish : Mirror finish

Application : Slitting and cutting of metal sheets, coils, and strips

Thickness : 0.2 mm 10 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS