Plastic Granulator Blades

Price 100 INR/ Piece

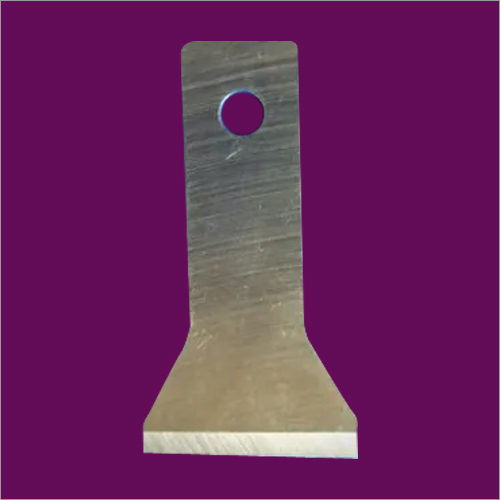

Plastic Granulator Blades Specification

- Design

- Robust, engineered for durability

- Shape

- Rectangular with beveled edge

- Precision

- High precision

- Surface Treatment

- Polished

- Type

- Granulator cutting blade

- Blade Material

- High carbon tool steel

- Application

- Plastic granulation and recycling

- Hardness

- 58-60 HRC

- Thickness

- 8 mm

- Sharpness

- Factory sharpened

- Edge Trimming

- Precisely ground edge for clean cutting

- Finish

- Smooth mirror finish

- Wear Resistance

- Excellent

- Customization

- Available for Size and Hole Placement

- Corrosion Resistance

- High

- Blade Length

- Up to 600mm

- Minimum Order Quantity

- 10 Pieces

- Compatible Machine Type

- Plastic Granulator, Shredder

- Heat Treatment

- Yes

- Packaging

- Wooden/Carton Box

Plastic Granulator Blades Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 4-5 Days

About Plastic Granulator Blades

Engineered for High Performance

Our granulator blades are meticulously crafted to deliver clean and consistent cuts in plastic recycling applications. Enhanced with a smooth mirror finish, factory-ground edges, and precision engineering, these blades maximize operational longevity and minimize downtime. Each blade undergoes thorough heat treatment to ensure advanced durability, making them a reliable choice for demanding industrial environments.

Custom Solutions for Your Operation

We understand that every operation has unique requirements. Thats why we offer customization options for blade length, thickness, and hole placements to perfectly match your machinerys specifications. All custom blades retain the same high level of hardness, sharpness, and wear resistance, guaranteeing a consistent and efficient plastic granulation process.

Dependable Packaging and Delivery

To ensure safe delivery, our blades are securely packed in wooden or carton boxes. Minimum order quantities as low as 10 pieces allow for flexible procurement. With a reputation as a trusted Indian manufacturer, exporter, and service provider, we guarantee quality and prompt supply for both domestic and international clients.

FAQs of Plastic Granulator Blades:

Q: How are these plastic granulator blades manufactured for enhanced durability?

A: Each blade undergoes high-precision engineering with advanced heat treatment, resulting in a robust structure and exceptional hardness (58-60 HRC). The use of high carbon tool steel further contributes to their excellent wear and corrosion resistance.Q: What types of machines are these blades compatible with?

A: These blades are specifically designed for plastic granulators and shredders, making them ideal for applications in plastic recycling and granulation.Q: When should I consider customizing the size or hole placement of the blades?

A: Customization is recommended if your granulator or shredder requires unique dimensions or hole patterns for optimal fitting and performance. Our team can manufacture blades up to 600mm in length with tailor-made hole placements to suit your specific machinery.Q: Where is the product manufactured and how is it packaged for shipping?

A: Our blades are manufactured in India and are carefully packed in either wooden or carton boxes to ensure secure transit. This packaging method protects the blades from potential damage during shipping.Q: What is the process for ordering and receiving custom-sized blades?

A: To order custom-sized blades, simply provide your specifications regarding blade length and hole placement. After confirmation, we will manufacture and deliver your customized blades, with a minimum order requirement of 10 pieces.Q: How should these blades be used for optimal cutting efficiency?

A: Install the blades into compatible plastic granulators or shredders, ensuring precise alignment as per your equipments requirements. Their precisely ground, sharp beveled edge guarantees clean and efficient cutting of plastic materials.Q: What are the main benefits of using these granulator blades in plastic recycling operations?

A: These blades offer high precision, excellent sharpness, and prolonged wear life, leading to reduced replacement frequency, lower maintenance costs, and consistently clean cutsensuring efficient and productive plastic recycling operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Knives And Blades For Plastic Category

Pelletizing Knives

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Hardness : 5860 HRC

Sharpness : Ultra Sharp Edge

Thickness : 610 mm

Blade Material : Other, High Speed Steel (HSS)

Strand Pelletizer Rotor

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Hardness : Up to 60 HRC

Sharpness : Industrial Grade

Thickness : Standard/Customized (Based on Application)

Blade Material : Other, High Speed Steel (HSS) / Tungsten Carbide

Die Face Cutting Knives

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Hardness : 5860 HRC

Sharpness : Razor Sharp

Thickness : 612 mm

Blade Material : Other, HighSpeed Steel (HSS)/Alloy Steel

Plastic Grinder Blades

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Hardness : 5862 HRC

Sharpness : Razor sharp edge

Thickness : 625 mm

Blade Material : Other, High Carbon Steel / Alloy Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS