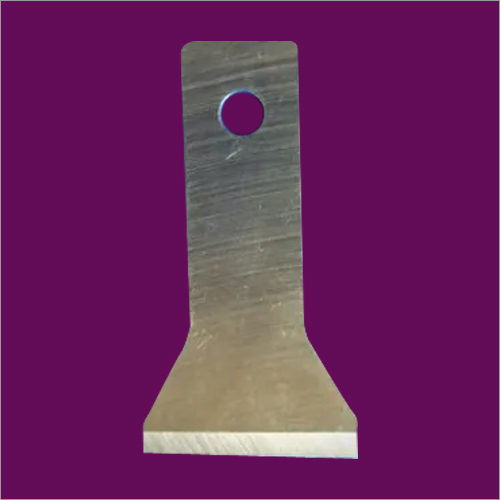

Strand Pelletizer Rotor

Price 100 INR/ Piece

Strand Pelletizer Rotor Specification

- Precision

- High Tolerance

- Shape

- Cylindrical Rotor

- Design

- Multi-blade, Customized Profile

- Surface Treatment

- Polished

- Type

- Strand Pelletizer Rotor

- Blade Material

- High Speed Steel (HSS) / Tungsten Carbide

- Application

- Plastic Granulating, Pelletizing Equipment

- Hardness

- Up to 60 HRC

- Thickness

- Standard/Customized (Based on Application)

- Sharpness

- Industrial Grade

- Edge Trimming

- Optimized for Clean Cut

- Finish

- Fine Mirror Finish

- Rotor Diameter

- 100 mm 400 mm

- Corrosion Resistance

- Excellent, Suitable for Humid Conditions

- Maintenance

- Easy to Replace and Maintain

- Life Cycle

- Extended Life with Wear Resistant Coating

- Rotor Length

- Up to 600 mm

- Max. Rotation Speed

- Up to 3000 RPM

- Delivery Condition

- Ready to Install

- Balancing

- Dynamically Balanced for Low Vibration

- Compatibility

- Fits Multiple Strand Pelletizer Models

- No. of Blades

- 6 to 24 (Customizable)

Strand Pelletizer Rotor Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 4-5 Days

About Strand Pelletizer Rotor

Versatile Applications Across Industrial Media

The Strand Pelletizer Rotor is engineered for a broad range of application media including all types of plastics. Its potent multi-blade and cylindrical design make it ideal for plastic granulating and pelletizing equipment. Commonly utilized in industries such as polymer processing, chemical manufacturing, and recycling, the rotors robust material also allows for other applications like edge trimming and powder granulation, ensuring flexibility and efficiency for diverse operational needs.

Sample Availability, Payment Terms, and Swift Delivery

Sample Strand Pelletizer Rotors are available upon request for a nominal charge, allowing for thorough assessment before bulk orders. Payment terms are flexible to accommodate client preferences, ensuring a smooth transaction process. Shipped goods are dispatched promptly, with delivery times carefully scheduled to meet urgent industrial timelines. Orders are efficiently packaged and tracked, promising swift delivery and satisfaction for clients who demand superior service and reliability.

FAQs of Strand Pelletizer Rotor:

Q: How do I select the correct Strand Pelletizer Rotor for my application?

A: Selecting the right rotor involves considering your pelletizers specificationssuch as desired rotor diameter, length, number of blades, and compatible materials. Provide your application details, and our expert team will recommend the ideal configuration tailored to your operational needs.Q: What makes this rotor suitable for humid environments?

A: This rotor features excellent corrosion resistance and a wear-resistant coating, ensuring reliable performance and longevity even in humid or challenging processing conditions.Q: When can I expect delivery after placing an order?

A: Delivery times are typically set based on order quantity and customization requirements. Most shipped goods reach clients within a mutually agreed timeframe, ensuring minimal downtime and efficient project management.Q: Where is this Strand Pelletizer Rotor manufactured and supplied from?

A: Our rotors are manufactured, exported, and supplied from India, ensuring high-quality standards and wide availability for domestic and international clients alike.Q: What is the maintenance process for this rotor?

A: Maintenance is straightforwardsimply replace worn blades and follow basic cleaning guidelines. The rotor is designed for easy installation and minimal upkeep, reducing downtime and operational costs.Q: How does the wear-resistant coating benefit pelletizer operators?

A: The advanced wear-resistant coating extends the rotors operational life, reduces maintenance intervals, and delivers consistently sharp and clean cuts, maximizing production efficiency and cost-effectiveness for operators.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Knives And Blades For Plastic Category

Pelletizing Knives

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Precision : High Tolerance Manufacturing

Blade Material : Other, High Speed Steel (HSS)

Hardness : 5860 HRC

Thickness : 610 mm

Die Face Cutting Knives

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Precision : High Precision

Blade Material : Other, HighSpeed Steel (HSS)/Alloy Steel

Hardness : 5860 HRC

Thickness : 612 mm

Plastic Grinder Blades

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Precision : High Precision

Blade Material : Other, High Carbon Steel / Alloy Steel

Hardness : 5862 HRC

Thickness : 625 mm

Blades For Shredder

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Precision : High Precision

Blade Material : Other, Alloy Tool Steel

Hardness : 5862 HRC

Thickness : 38 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS