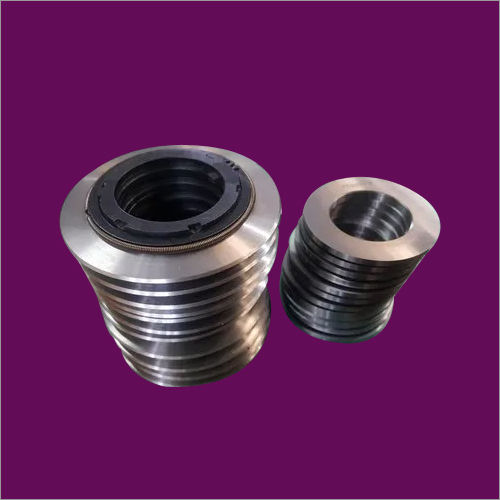

Pneumatic Crush-Cut and Scoring Knives Holder

Price 100 INR/ Piece

Pneumatic Crush-Cut and Scoring Knives Holder Specification

- Precision

- High precision alignment

- Shape

- Rectangular Holder

- Design

- Compact and modular

- Surface Treatment

- Anodized or Powder Coated

- Type

- Pneumatic Crush-Cut and Scoring Knife Holder

- Blade Material

- High Speed Steel (HSS) or Tungsten Carbide

- Handle Material

- Aluminum Alloy

- Application

- Used in slitting and cutting applications for paper, film, foil, textiles, and nonwoven materials

- Hardness

- HRC 58-62 (Blade)

- Thickness

- Adjustable cutting width

- Sharpness

- Industrial-grade sharpness

- Edge Trimming

- Consistent and precise edge quality

- Finish

- Smooth and corrosion-resistant

- Operating Pressure

- 5-6 bar (pneumatic system)

- Cutting Speed

- Up to 300 m/min depending on material

- Adjustment

- Tool-free blade exchange and positioning

- Compatibility

- Fits universal slitting shaft systems

- Installation

- Easy mounting on standard slitting machines

- Safety Features

- Integrated safety lock and guard

- Weight

- Roughly 1 - 1.5 kg depending on configuration

- Maintenance

- Low maintenance design, suitable for continuous operation

- Temperature Resistance

- -10°C to +80°C working range

- Blade Diameter

- Standard 100 mm (custom sizes available)

Pneumatic Crush-Cut and Scoring Knives Holder Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 4-5 Days

About Pneumatic Crush-Cut and Scoring Knives Holder

Efficient and Precise Cutting Solution

Engineered for high-speed, accurate slitting applications, this knife holder excels in delivering clean, stable cuts on various substrates. The industrial-grade sharpness and adjustable cutting width guarantee tailored results, while tool-free blade replacement optimizes productivity. Its compatibility with universal slitting shafts makes integration seamless across numerous production lines.

User-Friendly Operation and Maintenance

Operators benefit from the tool-free blade exchange and positioning, streamlining workflow and minimizing downtime. The holders low-maintenance design is ideal for continuous operation and enhances overall equipment reliability. Safety is ensured with integrated safety locks and guards, reducing risk during use.

Durable Construction for Extended Lifespan

Built with premium aluminum alloy and equipped with high-speed steel (HSS) or tungsten carbide blades, the holder is resistant to corrosion and suitable for harsh environments. A surface treatment of anodizing or powder coating further improves durability, and temperature resistance ranges from -10C to +80C, ensuring stability in various operating conditions.

FAQs of Pneumatic Crush-Cut and Scoring Knives Holder:

Q: How does the pneumatic knife holder improve cutting efficiency in industrial applications?

A: The pneumatic system allows for smooth, consistent pressure at 5-6 bar, enabling high-speed operation up to 300 m/min. Tool-free blade exchange and precise alignment reduce setup time, improving overall workflow and productivity in slitting operations.Q: What materials can be processed using this knife holder?

A: This holder is suitable for slitting and cutting materials such as paper, film, foil, textiles, and nonwoven fabrics. The industrial-grade blades ensure precise cuts across a variety of substrates.Q: When is blade replacement or adjustment needed, and how is it performed?

A: Blade replacement is recommended when decreased sharpness or inconsistent cuts are noticed. The holder features a tool-free mechanism, allowing quick and easy blade exchange or repositioning, minimizing machine downtime.Q: Where can the knife holder be installed, and is it compatible with existing equipment?

A: It mounts directly onto standard slitting machines and fits universal slitting shaft systems, making it adaptable to most industrial setups without complex modifications.Q: What is the process for maintaining the knife holder for optimal performance?

A: Routine inspection for wear, cleaning, and timely blade replacement are recommended. Its low-maintenance design ensures it remains reliable during continuous operation, requiring minimal service interventions.Q: How do the integrated safety features benefit the user during operation?

A: Safety locks and protective guards prevent accidental contact with moving blades, providing enhanced operator safety and compliance with industrial standards.Q: What are the benefits of choosing this knife holder for slitting applications?

A: Users enjoy high precision, ease of use, robust durability, and superior edge trimming quality. The modular design supports both standard and custom installations, offering flexibility and consistent performance for manufacturers, exporters, and service providers in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Circular Knives Category

Crush Cut Knives

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Used in Slitting and Trimming Flexible Materials, Foil, Film, Paper, and Textiles

Surface Treatment : Other , Polished, Rustresistant Coating

Finish : Mirror Finish

Shape : Round (Circular)

Slitting Top Knives Holder

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Rotary slitting machines, paper and film cutting

Surface Treatment : Other , Polished

Finish : Smooth corrosionresistant finish

Shape : Rectangular (Holder), Circular (Knife Mount)

Core Cutting Knives

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Paper core cutting, film slitting, industrial processing

Surface Treatment : Other , Polished

Finish : Mirror finish

Shape : Rectangular with beveled edges

Scoring Knives

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Glass Cutting, Scoring Ceramic Tiles, and Sheet Material

Surface Treatment : Other , Polished

Finish : Mirror Finish

Shape : Rectangular Blade with Angled Edge

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS